Konference DIAGO 2025

Na konci ledna jsme se zúčastnili konference DIAGO 2025, kde jsme měli technickou přednášku, prezentovali naši technologii, navázali nové kontakty a utužili ty stávající. Děkujeme všem účastníkům za dobrou atmosféru!

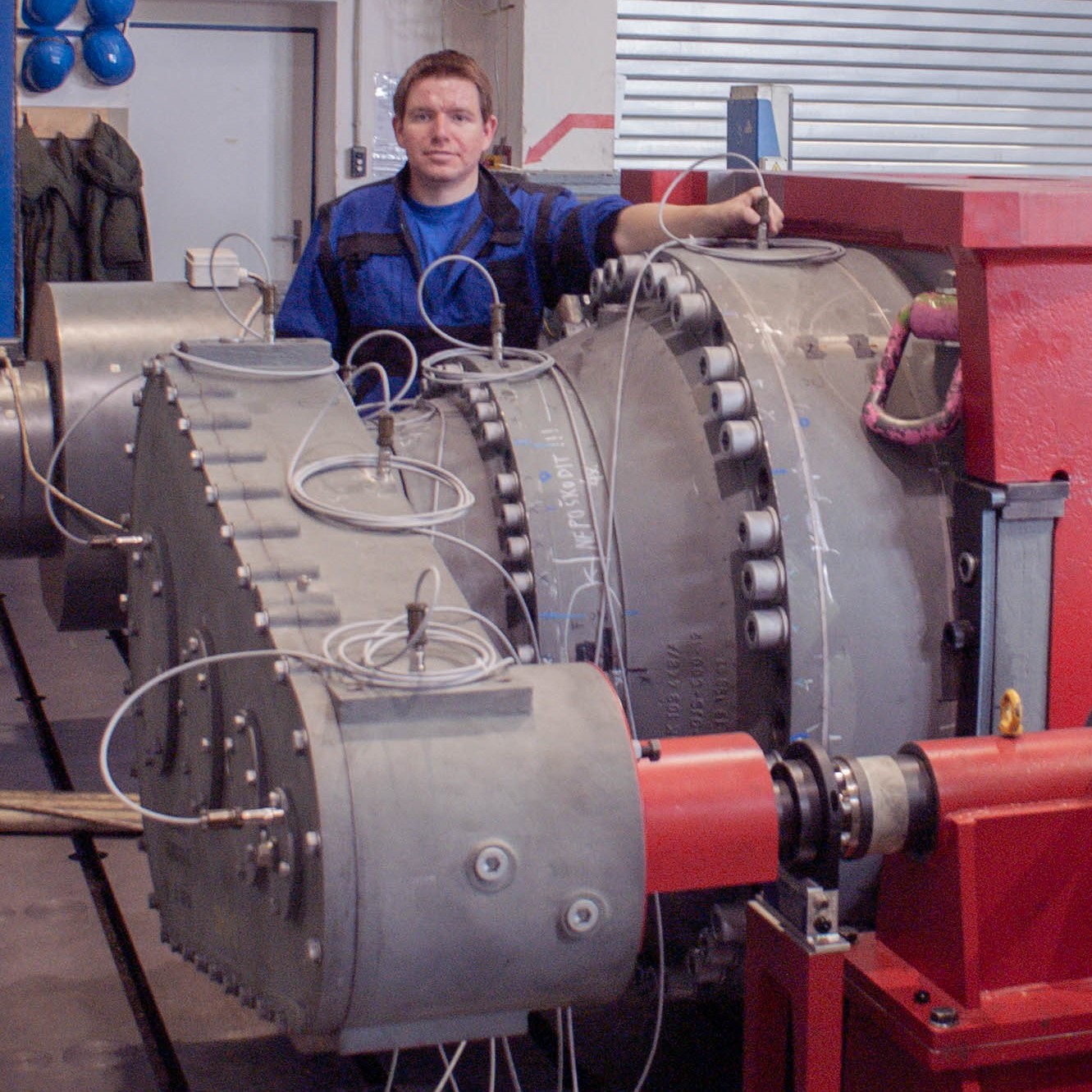

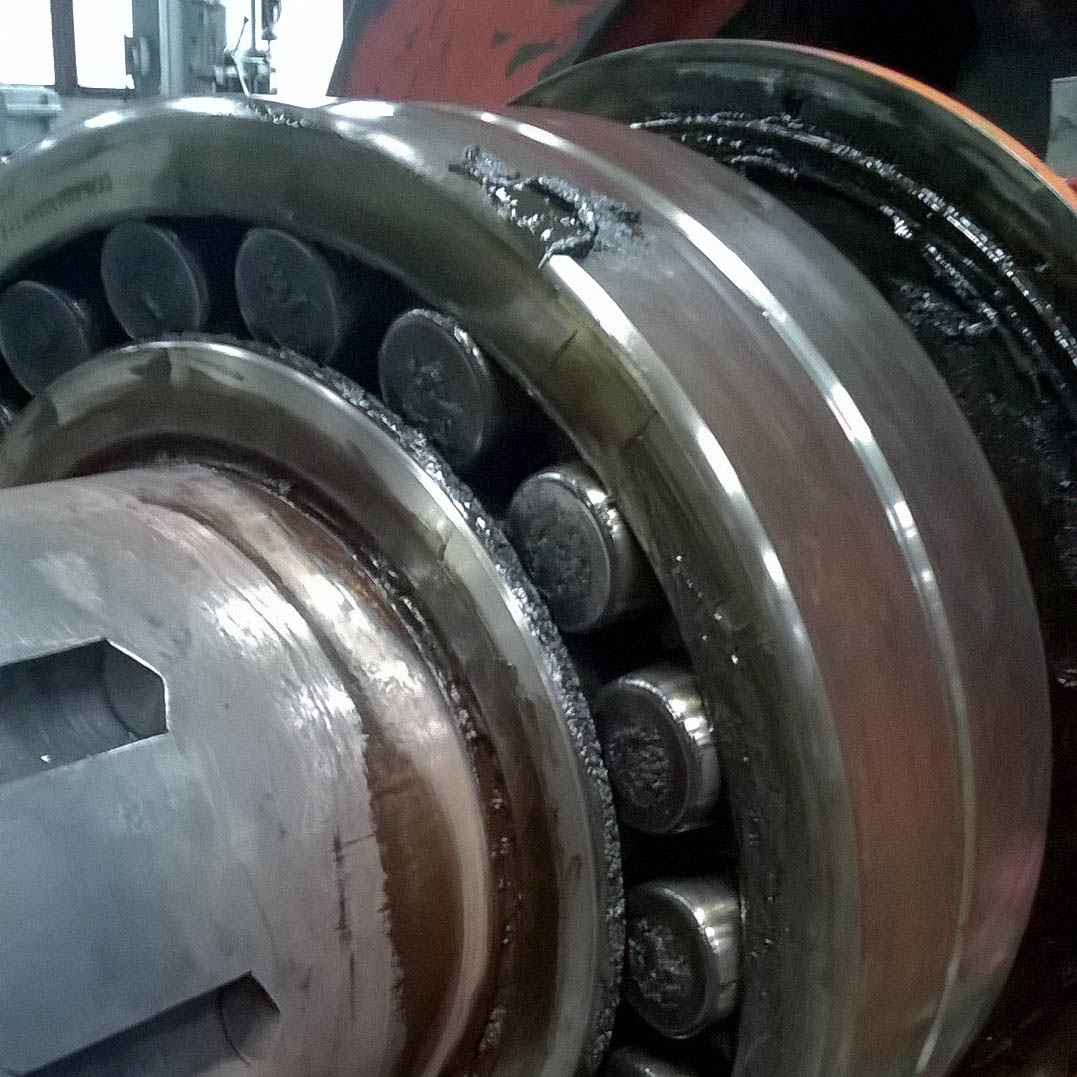

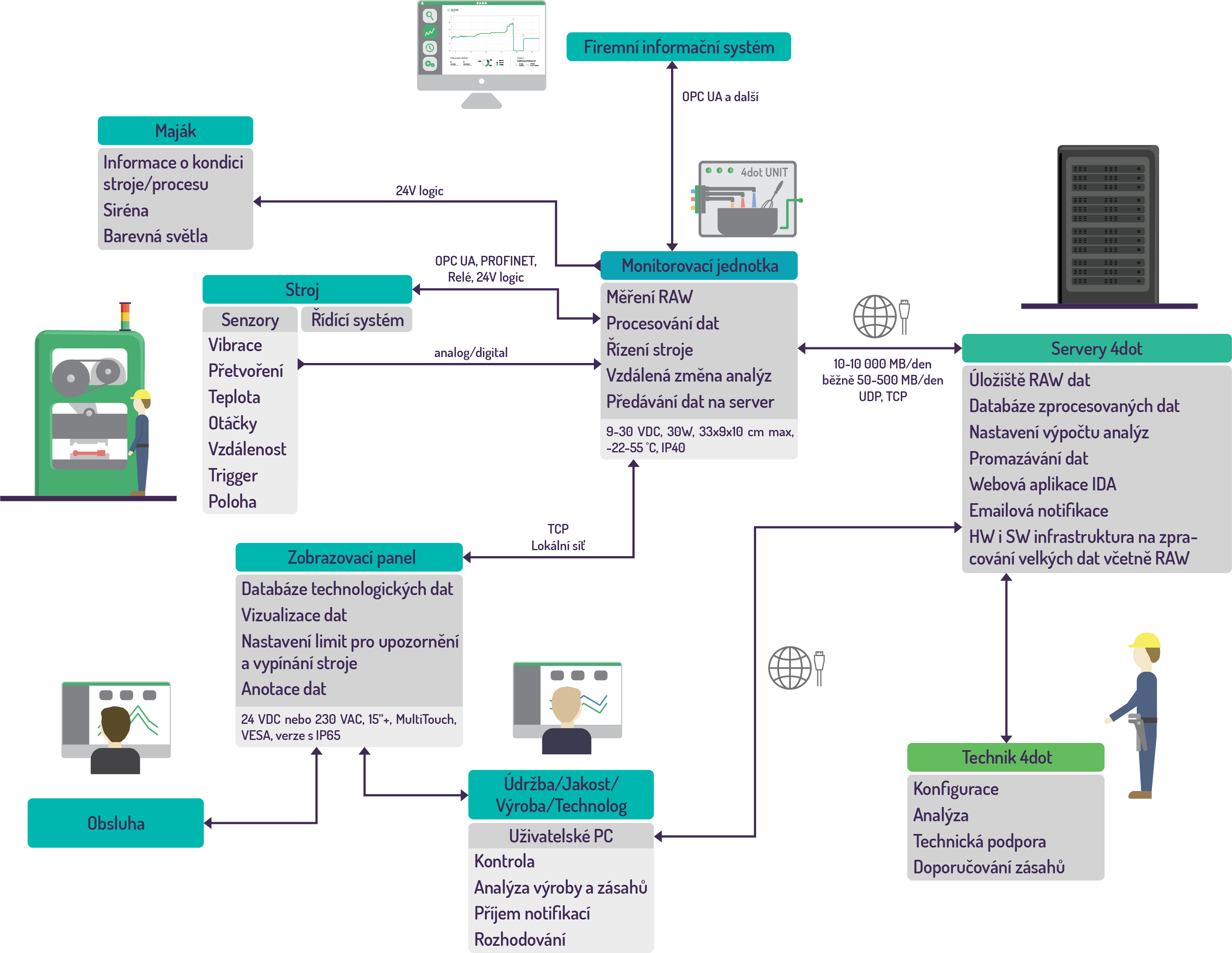

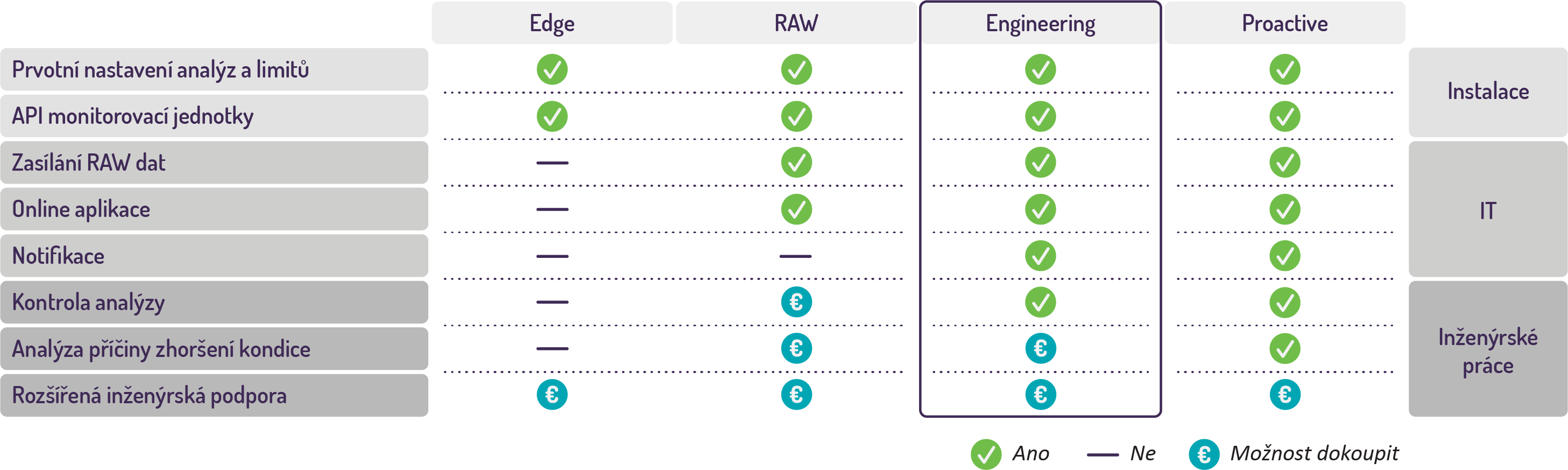

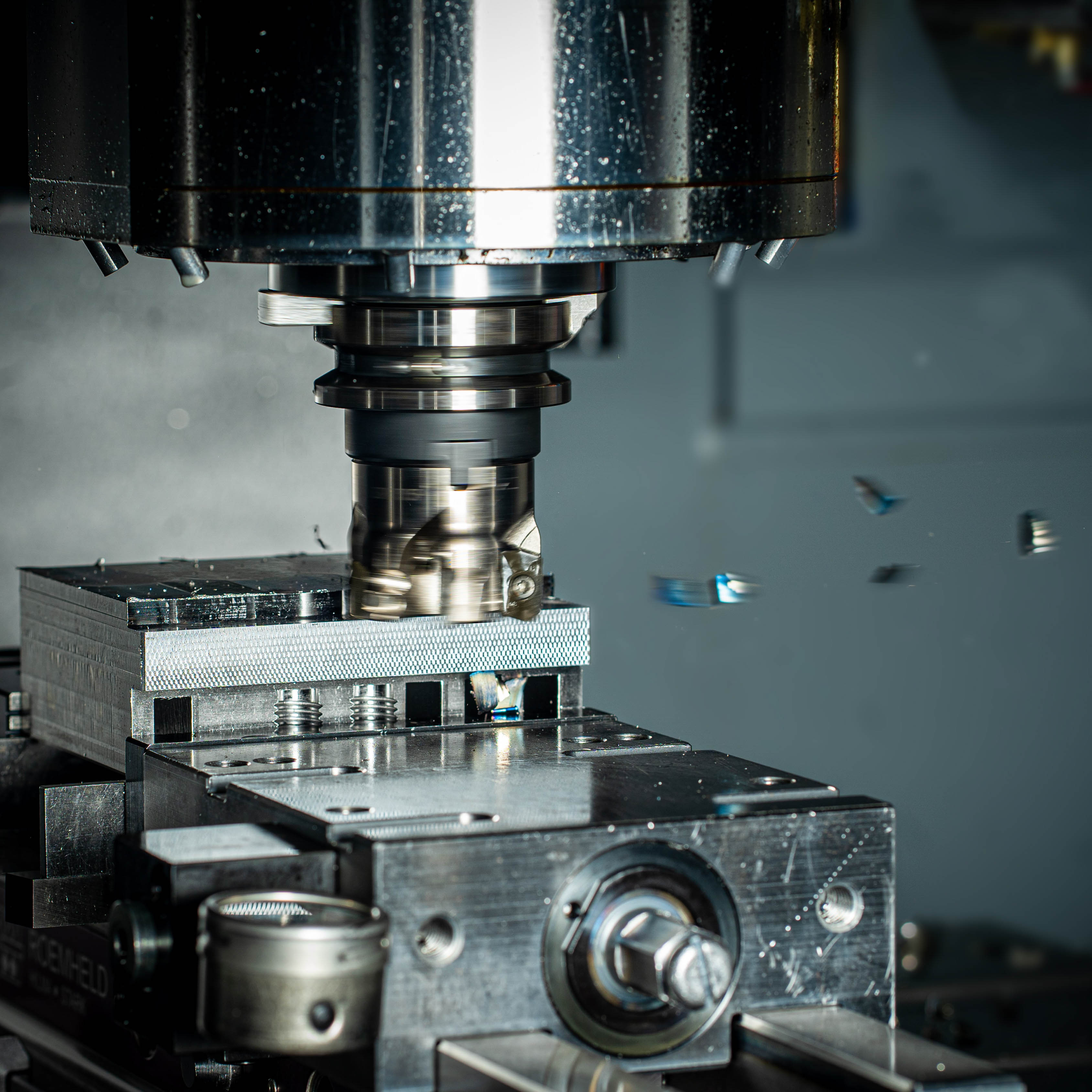

Implementace technického a procesního monitoringu

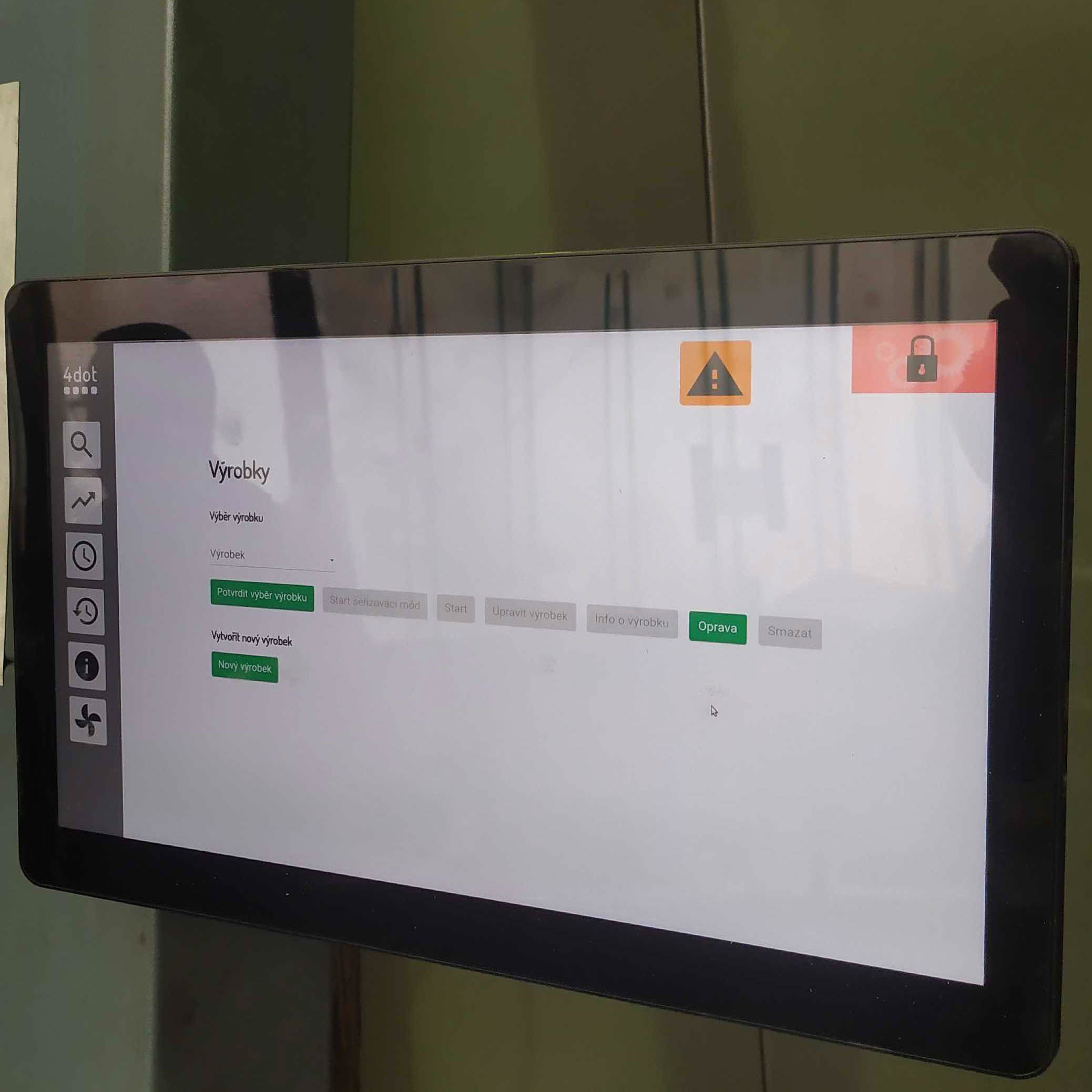

Náš článek ze 14. kovárenské konference se zabývá možnostmi přenosu dat a propojování systémů. V příspěvku jsou uvedeny i příklady implementace monitorovacího systému v praxi, včetně použitých senzorů a způsobů zpracování dat.

Výzva československému průmyslu: Místo jednoho dokonalého několik dobrých řešení

Nesčetněkrát jsem také slyšel, že my Češi jsme přišli s reformací a úspěšně ji vyvezli na Západ. A anglosaský svět, tedy západní Evropa a Spojené státy, na tom postavil svoji ekonomickou prosperitu.